SCUBA diving opens up a fascinating underwater world, but it comes with its own set of safety challenges. One of the most critical aspects of maintaining safety for divers is ensuring that their SCUBA tanks are in top condition. This is where hydrostatic testing comes into play. At Serviced Fire Equipment, Inc., we specialize in water jacket hydrostatic testing to ensure your SCUBA tanks are safe for use. Let’s dive into the importance of this process, when additional procedures like eddy current testing and internal bead blasting are required, and how often these tests must be conducted.

Understanding Hydrostatic Testing

Hydrostatic testing is a method used to inspect the integrity and safety of pressurized vessels, including SCUBA tanks. The process involves filling the tank with water and pressurizing it to a level higher than its normal operating pressure. The tank is then placed in a water jacket, a chamber filled with water, and the pressure is increased. Any expansion of the tank is measured by the amount of water displaced from the water jacket.

This test helps identify any weaknesses or flaws in the tank that could lead to catastrophic failure during a dive. It’s a critical safety measure that ensures the tank can withstand the pressures it will face underwater.

Why Hydrostatic Testing is Crucial

- Safety Assurance: The primary reason for hydrostatic testing is to ensure the safety of the diver. A failed SCUBA tank can lead to drowning or serious injury. Regular testing minimizes the risk of tank rupture.

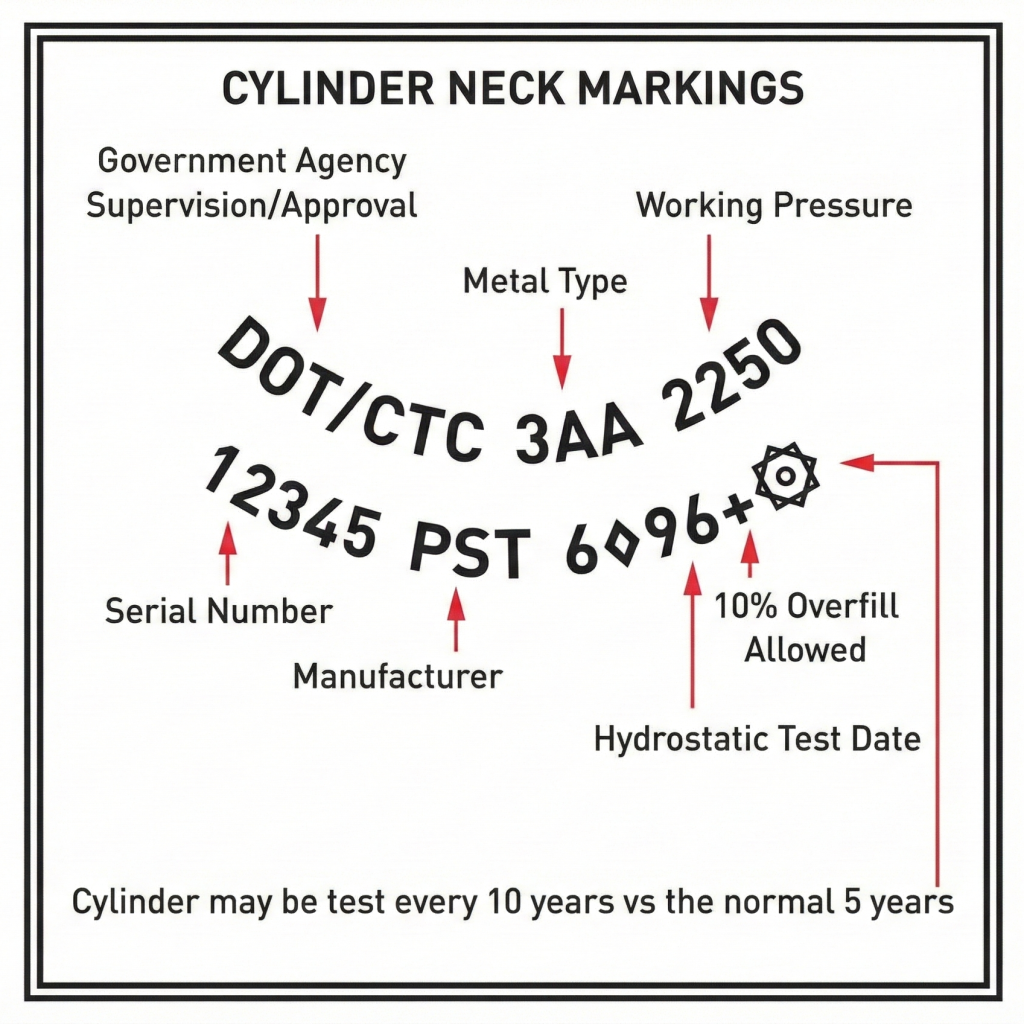

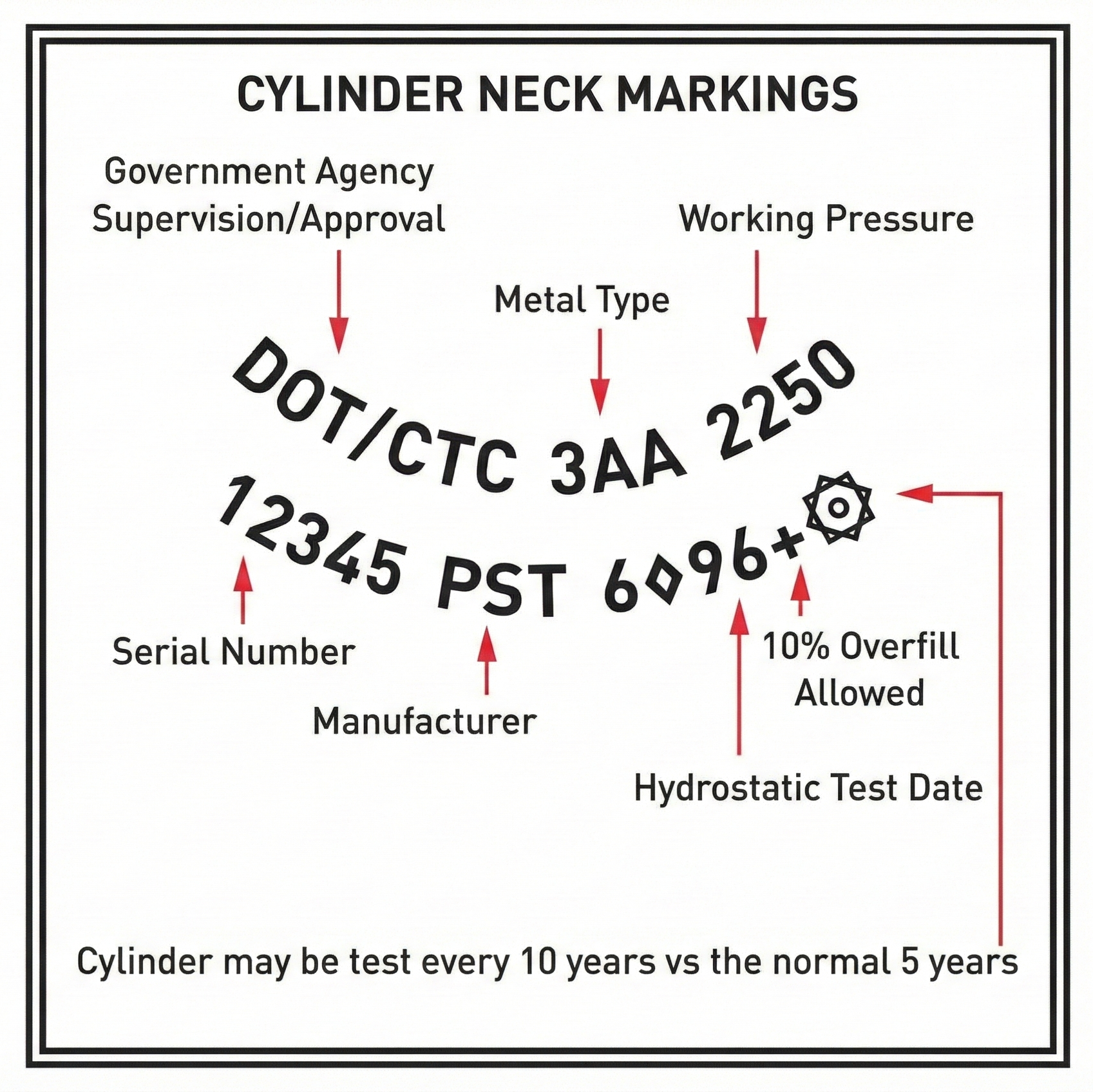

- Compliance with Regulations: Various regulatory bodies, including the Department of Transportation (DOT) in the United States, mandate regular hydrostatic testing for SCUBA tanks. Compliance with these regulations is necessary for legal and insurance purposes.

- Tank Longevity: Regular testing and maintenance can extend the life of a SCUBA tank. Identifying and addressing issues early prevents more severe damage that could render the tank unusable.

- Performance Reliability: A well-maintained tank ensures that divers can rely on their equipment to perform as expected, providing peace of mind during dives.

When is Eddy Current Testing Needed?

Eddy current testing is a non-destructive method used to detect surface and sub-surface flaws in metal objects. For SCUBA tanks, it is particularly useful for identifying cracks and other defects that are not visible to the naked eye.

Eddy current testing is often required in the following scenarios:

- Aluminum Tanks: Aluminum SCUBA tanks are more prone to developing cracks, especially around the neck and threads. Eddy current testing is used to detect these issues.

- Post-Hydrostatic Testing: If a hydrostatic test indicates potential weaknesses or irregularities, eddy current testing can provide a more detailed analysis of the tank’s condition.

- Older Tanks: Tanks that have been in use for many years or have unknown histories may benefit from the additional scrutiny provided by eddy current testing.

When is Internal Bead Blasting Needed?

Internal bead blasting is a process used to clean the interior surfaces of SCUBA tanks. This procedure is necessary when there is significant corrosion, rust, or other contaminants inside the tank that could compromise its integrity or contaminate the air supply.

Bead blasting involves projecting small glass or ceramic beads at high velocity against the internal surfaces of the tank, effectively removing debris and leaving a clean, smooth surface. This process is typically needed:

- After Long Periods of Disuse: Tanks that have been stored for long periods may develop internal corrosion or contamination.

- Following Hydrostatic Testing: If hydrostatic testing reveals significant internal corrosion, bead blasting is used to clean the tank before it is returned to service.

- During Refurbishment: Tanks undergoing complete refurbishment often require internal bead blasting to ensure they are in the best possible condition.

How Often Must SCUBA Tanks Be Tested?

The frequency of hydrostatic testing for SCUBA tanks depends on the material of the tank and regulatory requirements. In the United States, the DOT mandates the following:

- Aluminum Tanks: These tanks must be hydrostatically tested every five years. However, some aluminum tanks made with certain alloys may require more frequent testing.

- Steel Tanks: Steel SCUBA tanks also require hydrostatic testing every five years. Steel is generally more durable than aluminum, but it is still susceptible to corrosion and other forms of wear and tear.

In addition to hydrostatic testing, visual inspections are recommended annually to check for any obvious signs of damage or wear. These inspections can help identify issues early and ensure that tanks remain safe between hydrostatic test intervals.

Hydrostatic Testing at Serviced Fire Equipment, Inc.

At Serviced Fire Equipment, Inc., we are dedicated to ensuring the safety and reliability of your SCUBA tanks through our expert hydrostatic testing services. Our water jacket hydrostatic testing process is thorough and precise, providing you with the confidence that your tanks are in optimal condition.

Here’s what sets our testing services apart:

- State-of-the-Art Equipment: We use the latest technology to conduct hydrostatic tests, ensuring accurate and reliable results.

- Experienced Technicians: Our team of skilled technicians has extensive experience in SCUBA tank testing and maintenance, allowing us to provide the highest level of service.

- Comprehensive Testing: In addition to hydrostatic testing, we offer eddy current testing and internal bead blasting to address all aspects of tank safety and maintenance.

- Regulatory Compliance: We ensure that all testing is conducted in accordance with DOT regulations and industry standards, so you can be assured of compliance and safety.

Conclusion

Hydrostatic testing is a vital process for maintaining the safety and reliability of SCUBA tanks. Regular testing, combined with additional procedures like eddy current testing and internal bead blasting when necessary, ensures that tanks remain in top condition and safe for use. At Serviced Fire Equipment, Inc., we are committed to providing the highest quality testing services to keep divers safe and equipment performing at its best. Whether you’re a professional diver or an enthusiast, trust us with your SCUBA tank maintenance needs and dive with confidence.

Safe Diving Starts Here: SCUBA Tank FAQs You Can Trust

Q1: How often do SCUBA tanks need to be hydrostatic tested?

The SCUBA tanks usually require hydrostatic testing after every five years to check on their strength and safety. The test also determines the ability of the tank to bear pressure without getting weakened which is a feature that keeps the divers safe and assured when using it underwater.

Q2: How to hydro test a scuba tank?

Hydro testing entails filling the tank with water and putting it into a special chamber and pressurizing it to check expansion limits. This process must only be conducted by certified professionals since it will guarantee that the tank is of high standards regarding safety.

Q3: How long is a scuba tank good for?

Maintained scuba tanks have a lifespan of 20 to 30 years, provided they are not subject to hydro tests and annual examination. Frequent servicing and storage assist in the lengthening of life and safety to achieve consistent performance underwater.

Q4: Why Is Hydrostatic Testing Critical for SCUBA Cylinders?

Hydrostatic testing is critical for SCUBA cylinders because it verifies structural integrity under pressure, detects metal fatigue or hidden damage, ensures compliance with safety regulations, prevents catastrophic failure underwater, and protects divers by confirming cylinders can hold gas.

Q5: What Does the SCUBA Acronym Stand For?

SCUBA stands for Self-Contained Underwater Breathing Apparatus. It refers to equipment that allows divers to breathe independently underwater by carrying a compressed air supply, enabling safe exploration, training, and commercial or recreational diving activities.

Q6: Is it possible to use an aged scuba tank without hydro testing?

Diving into a tank that has not been hydro tested is unsafe and in most cases not permitted by the dive shops. Failure may exist due to untested hidden damage or metal fatigue. Never dive without checking hydro dates so as to have safe and reliable diving.

Q7: What is the life of mini scuba tanks?

Small scuba tanks typically hold a few minutes of air which may be 5 to 15 minutes with size and depth. They are perfect for short, shallow tasks but they must always be used responsibly and with adequate safety awareness.