Hydrostatic Testing Services

At Serviced Fire Equipment, we elevate the standards of hydrostatic testing, a crucial process where components such as pressurized containers are tested for strength, expansion and leaks using pressurized liquid. As a leading DOT Approved hydrostatic testing facility, we combine state-of-the-art technology with unparalleled expertise to offer comprehensive testing services.

Wide Range of Cylinders Tested

We specialize in hydrostatic testing for a diverse array of cylinders, including but not limited to:

• Scuba Tanks

• Paintball Tanks

• Medical Oxygen Tanks

• Chlorine Tanks

• Beverage Tanks

• Kegerator Tanks

• Nitrogen Tanks

• CO2 Beverage Tanks

• Self-Contained Breathing Apparatus (SCBA) Cylinders

• Propane Tanks

• Low-Pressure Aluminum Cylinders

• Compressed Gas Cylinders

• High-Pressure Aluminum Compressed Gas Cylinders

• Fiber-Reinforced High-Pressure Cylinders

• Marioff High Fog Cylinders

• CO2 Fire Extinguishers

We pride ourselves on our ability to handle almost all cylinders that carry a DOT number, ensuring versatility and inclusivity in our services.

Process of Refurbishment

Inspection

Cylinders undergo a rigorous inspection by our DOT-qualified technicians to ensure they are fit for testing.

Testing Procedure

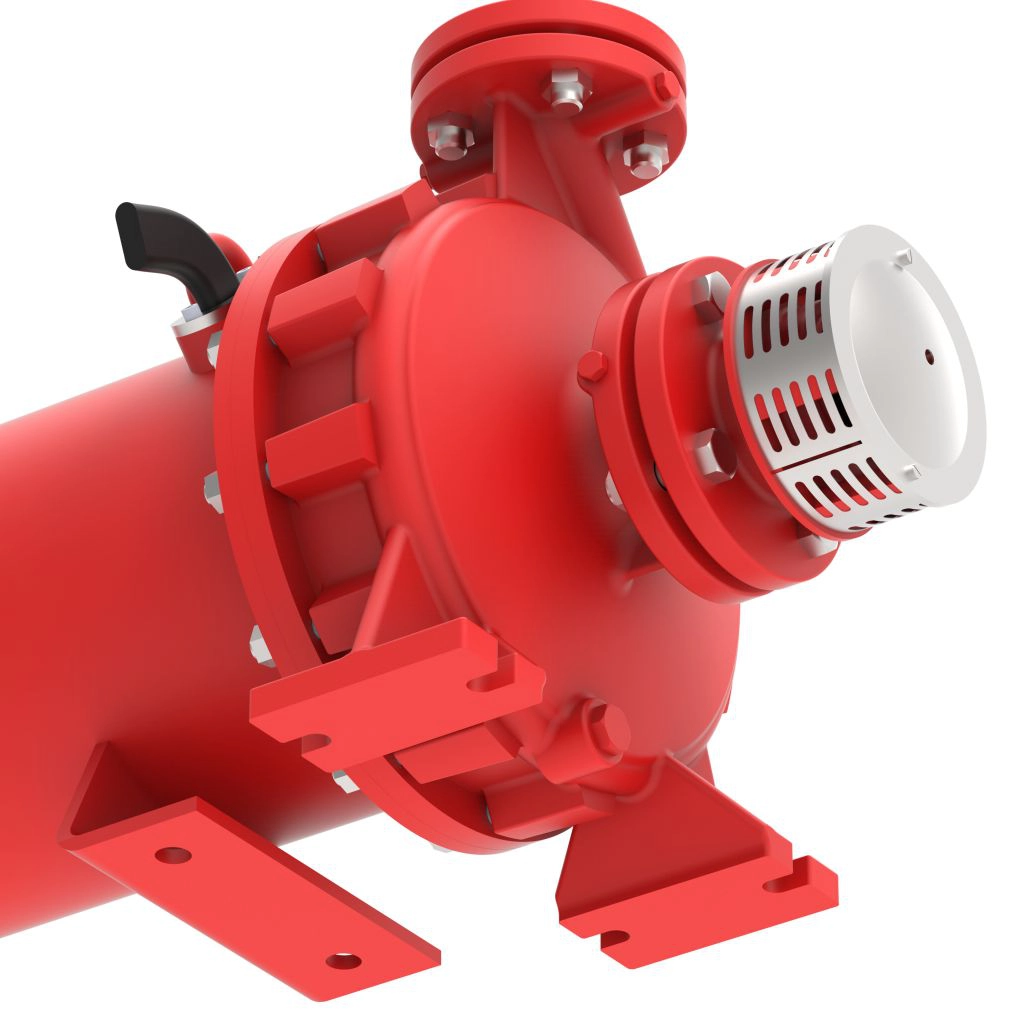

Cylinders are placed inside a water jacket and pressurized with water to measure expansion and test integrity.

Requalification Records

Successful tests are documented with requalification records, and cylinders are marked with RIN identification and the retest date.

Condemnation Process

Cylinders that fail the test are marked as "Condemned," and with the owner's permission, are rendered unable to hold pressure.

Why Choose Serviced Fire Equipment?

Expertise and Certification

As a fully licensed, DOT approved hydro testing facility, we can hydrostatically test the following DOT cylinders 3A, 3AA, 3AL, 3HT, 4B, 4B240ET, 4BA, 4BW, and Special Permit(s): 7235, 7277, 7737, 7945, 8059, 8162, 9421, 9634, 9791, 9894, 9909, 10019, 10147, 10776, 10869, 10915, 10945, 11005, 11194, 11598, 12079, 12479, 12706, 13483, 13488, 13583, 14003, 14339, 14387, 14932

Comprehensive Service

We offer a complete and thorough approach to cylinder care, ensuring that every step is handled with precision and expertise. From arranging transportation to conducting detailed inspections, our services cover every aspect of cylinder maintenance. In addition to our internal bead blasting, O2 cleaning, and cylinder painting services, we also specialize in hydrostatic testing. Hydrostatic testing is a crucial step in ensuring the safety and longevity of your cylinders, and we take it seriously. Our team conducts hydrostatic testing to the highest industry standards, giving you peace of mind with every cylinder we service.

Geographical Reach

Serviced Fire Equipment proudly extends its services to a wide geographic area, making our expertise accessible and convenient for clients in numerous locations. Whether you're located in Florida or beyond, we are equipped to handle your hydrostatic testing needs with ease. Even if you're outside of the state, you can ship your empty cylinders directly to our certified hydrostatic test station for safe and compliant testing. Once the testing is complete, we’ll promptly ship your cylinders back to you, ensuring you receive top-quality service no matter where you are. Our goal is to provide seamless, reliable, and efficient cylinder maintenance for all our customers, regardless of location.

Customer-Centric Approach

At Serviced Fire Equipment, we are dedicated to delivering personalized services that are uniquely tailored to meet the specific needs of each individual client. We understand that no two clients have the same requirements, which is why we take the time to listen and customize our approach to ensure complete satisfaction. Our commitment to reliability means you can trust us to handle your fire equipment needs with the utmost care and precision, regardless of the scale or complexity. Whether it’s hydrostatic testing, cylinder inspections, or any of our other specialized services, we work closely with you to provide a seamless and dependable experience from start to finish.

Hydrostatic Testing Frequency

Understanding the testing requirements of your equipment is crucial for maintaining safety and compliance. We provide guidance on testing frequency based on DOT regulations and can assist in interpreting the requirements for different types of cylinders.

Common Testing Requirements

• DOT-3AL Gas Cylinders: Test every 5 years, unlimited life.

• DOT-3HT Gas Cylinders: Test every 3 years, 24-year life.

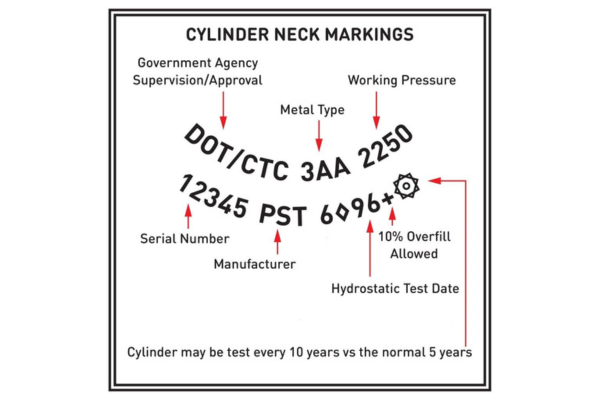

• DOT-3AA Gas Cylinders: Test every 5 years, unlimited life (or 10 years if stamped with a star).

• Special Permit (SP) Cylinders: Specific requirements based on the permit.

Cylinder Markings and Compliance

Our hydrostatic testing services ensure that your cylinders comply with U.S. and Canadian standards set by organizations like ASTM and ASME. We ensure that all cylinders are correctly marked post-testing, adhering to legal and safety standards.

Interested in partnering with us

- Phone: 727-620-3473

- Email: Info@ServicedFireEquipment.com

- Location: 3200 62nd Ave N, St. Petersburg, FL 33702

Whether you need hydrostatic testing or other cylinder services, Serviced Fire Equipment is just a phone call or email away. As the go-to hydrostatic testing facility for cylinders in St. Petersburg, Clearwater, Tampa, Largo, Pinellas Park, Bradenton, Sarasota, Lakeland, Venice, Brandon, Palm Harbor, Riverview, Winter Haven, Wesley Chapel, Spring Hill, Dunedin, Oldsmar, Plant City, Zephyrhills, Tarpon Springs, New Port Richey, Sebring, North Port, Port Charlotte, Orlando, Kissimmee, Winter Park, Clermont, Leesburg, and Ocoee, we are here to provide expert service. Let us handle the intricacies of your cylinder testing and maintenance needs.

Contact Us

Interested in partnering with us

Whether you need hydrostatic testing or other cylinder services, Serviced Fire Equipment is just a phone call or email away. As the go-to hydrostatic testing facility for cylinders in St. Petersburg, Clearwater, Tampa, Largo, Pinellas Park, Bradenton, Sarasota, Lakeland, Venice, Brandon, Palm Harbor, Riverview, Winter Haven, Wesley Chapel, Spring Hill, Dunedin, Oldsmar, Plant City, Zephyrhills, Tarpon Springs, New Port Richey, Sebring, North Port, Port Charlotte, Orlando, Kissimmee, Winter Park, Clermont, Leesburg, and Ocoee, we are here to provide expert service. Let us handle the intricacies of your cylinder testing and maintenance needs.

Our Water Jacket Hydrostatic Testing Process

Preparation

We begin by thoroughly inspecting your cylinders for any visible damage, corrosion, or defects. After cleaning the exterior to remove contaminants, we set up the water jacket apparatus, ensuring proper instrumentation and sealing for accurate testing.

Submerging the Cylinder

Carefully lowering the cylinder into the water jacket enclosure, we ensure full submersion and secure positioning to prevent movement during testing.

Pressurization

Gradually introducing pressure into the water jacket, we monitor and control the pressure to reach the specified test pressure for your cylinder. During the hold period, we meticulously inspect for leaks or weaknesses in the cylinder's structure.

Inspection

Conducting thorough visual inspections and leak detection tests, we assess the cylinder's exterior and structural integrity for any signs of damage or deformation.

Depressurization and Evaluation

After completing the hold period, we depressurize the system and carefully remove the cylinder for post-test evaluation. Analyzing the test results, we provide detailed recommendations and remedial actions if any defects are detected.

Trust Serviced Fire Equipment for Your Hydrostatic Testing Needs When it comes to hydrostatic testing, trust the experts at Serviced Fire Equipment to deliver reliable, professional, and comprehensive services. With our years of experience, dedication to quality, and commitment to customer satisfaction, you can rest assured that your cylinders are in good hands.

Contact us today to schedule your water jacket hydrostatic testing and ensure the safety and compliance of your equipment. Let Serviced Fire Equipment be your partner in protecting what matters most.